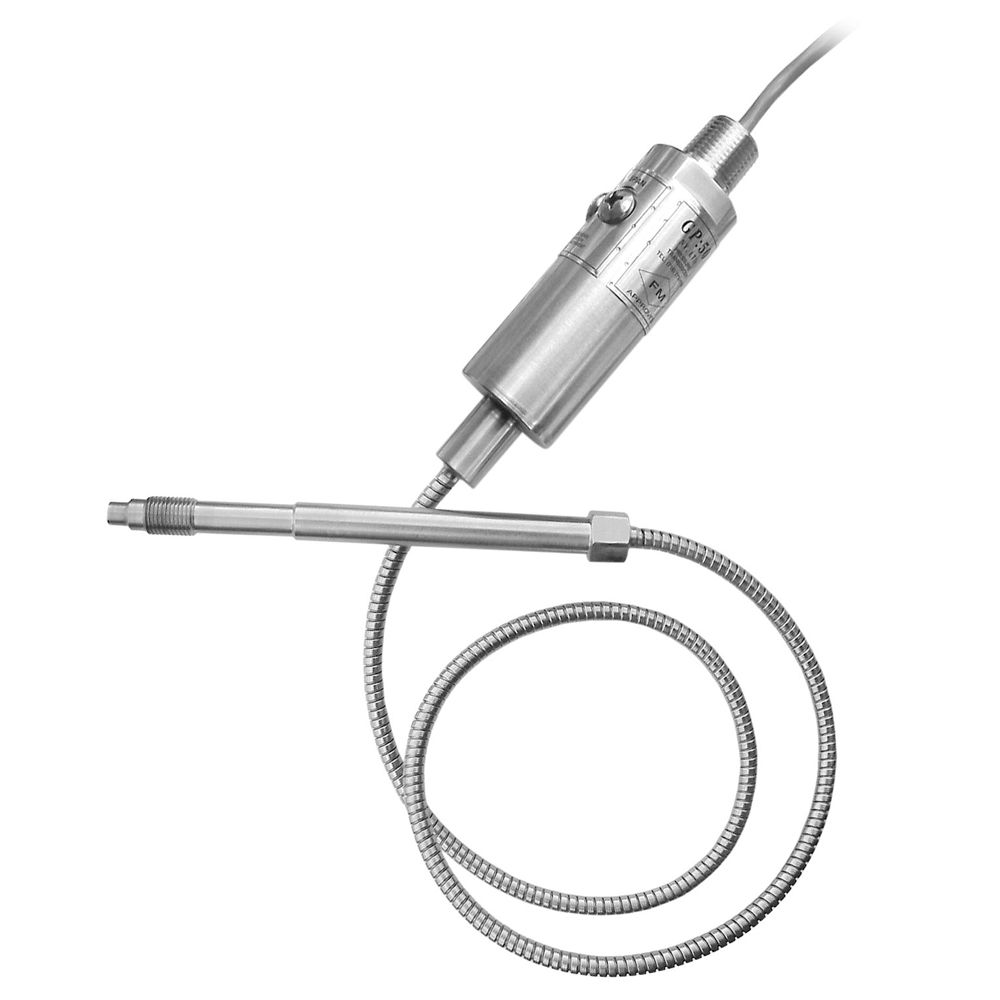

Hazardous Environments Plastic Melt Pressure Transducer / Transmitter

| Model Specs | |

|---|---|

| Model: | 130X, 131X, 230X, 231X, 330X, 331X, 130P, 131P, 230P, 231P, 330P, 331P, 330Z, 331Z | Range: | 0-500 to 0-30,000 PSI | Accuracy: | ±0.25% FSO, RSS (0-5000 psi & higher), ±0.5% FSO, RSS (0-500 and 0-3500 psi) | Certification: | X = FM Explosion Proof, P = FM & CSA Explosion Proof, Z = FM & CSA Intrinsically Safe | Warranty: | Product Warranty |

All Products are 100% made in the USA

All Products are 100% made in the USA

The GP:50 product line of melt pressure transducers and transmitters are based on the proven bonded strain gage principle successfully utilized in thousands of applications. Our unique design incorporates a heavier sensor allowing a thicker tip diaphragm, provides better linearity, and reduces costs.

The design incorporates an extremely small capillary tubing that transmits the media pressure to the strain gage sensor and mating electronics via a mechanical fill fluid. (Mercury is the standard, silicone oil, mineral oil and Nak are readily available depending on the application).

Additional Features:

- Rugged, all-welded, all stainless steel construction.

- Interchangeable with existing systems.

- Many options available, Hastelloy C-276 or Boron – Hardening

- FM Explosion-Proof and FM Intrinsically Safe Approved

(Class I, Division I, Groups A, B, C, D) - CSA Intrinsically Safe Approved

- Internal Calibration Resistor set to 80% ± 0.5% FSO

(Explosion Proof model only) - Zero and Span controls, approximately ± 20% FSO